The matter in question is largely based around the appropriate application of the key control elements found in fan coil units, i.e. control valves.

Control valves are one of the most important components of water distribution, air conditioning and heating systems. Consequently, their appropriate selection is a prerequisite for the correct operation and capacity of a fan coil unit. This, in turn, translates into the correct functioning of the water distribution system as a whole.

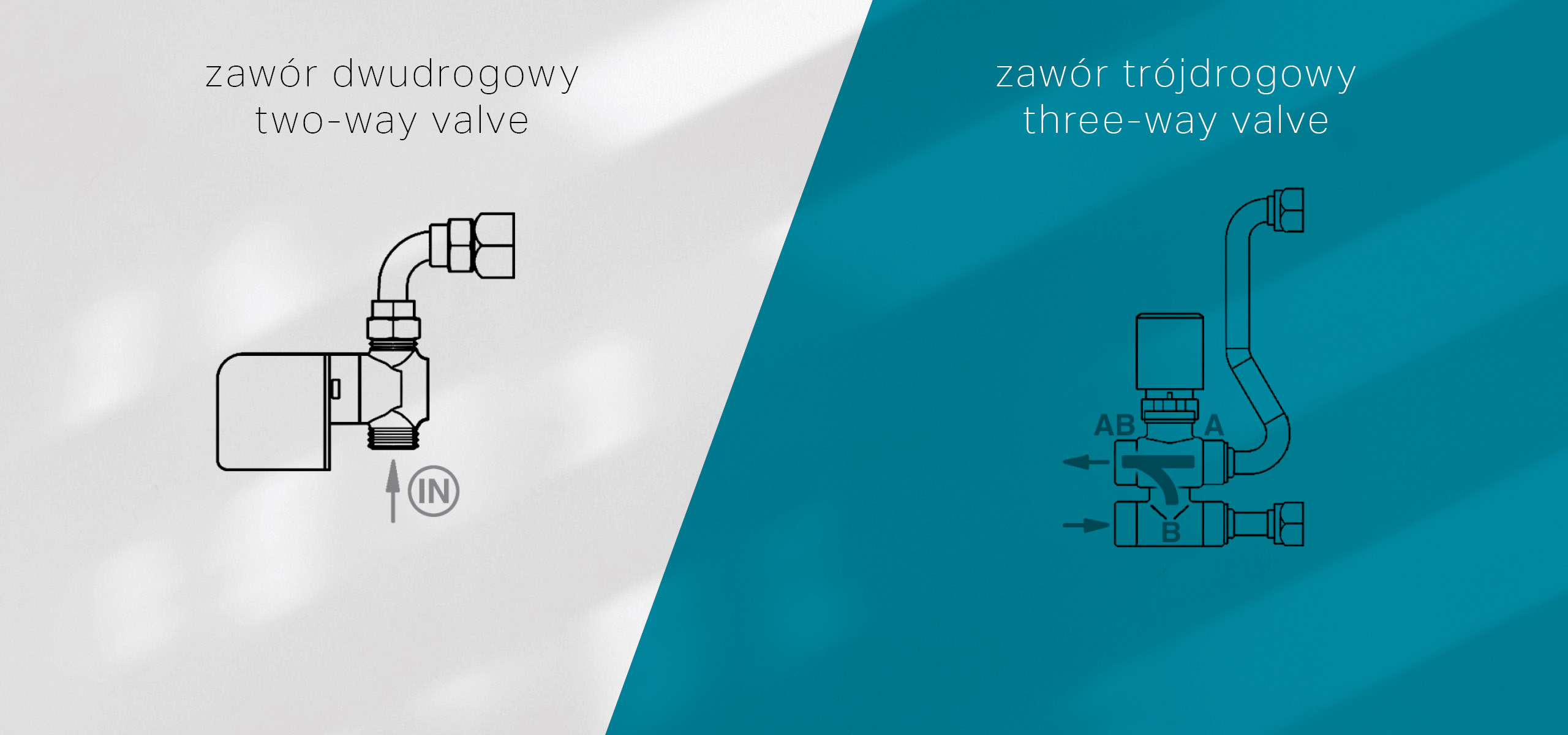

The basic criteria for setpoint adjustment and control of fan coil units are the types of valves used:

- two-way valve

- three-way valve

And the method of valve control:

- ON/OFF

- stepless (0-10V)

- PWM

- three-point

The basic parameter and task of a fan coil is to maintain the temperature at the value set by the controller. For this to be the case, the capacity of the system must change over time.

These changes are caused indirectly by the automation system and directly by the heat exchanger and control valves in the hydraulic system. The system’s response to the changing cooling load or heat load is to adjust the quantity or temperature of the medium.

Control methods:

- QUANTITY CONTROL – the capacity of the unit is controlled by the quantity of the flowing medium.

- QUALITY CONTROL – the capacity of the unit is controlled by changes in the temperature of the flowing medium.

In systems which use two-way valves, the capacity of a cooler or heater is controlled by a valve which, depending on the type of the control method, changes the quantity of the water flowing through the exchanger, or by means of two states: flow and lack of flow. In systems which use three-way valves to control the capacity of fan coil units, in periods when there is no need to heat or cool, the stream of water is directed through the bypass of the valve, so the total water flow in the system is constant.

The room temperature control system consists in continuous measurement and comparing the results with the setpoint values. If the measured room temperature differs from the setpoint value, the controller corrects the position of the valve. This affects the quantity of the medium and the capacity of the system, which, of course, changes the room temperature. This compensates the impact of disturbances, such as changes to the outside temperature, the opening of a window, additional heat gain from people, etc. The result is constant perceived room temperature. To what extent this temperature is stable and to what extent the system is able to precisely correct these disturbances greatly depends on the choice of valves, but also on the assumed control methods, among others. The control methods mentioned above are briefly defined below.

The control signal can take one of the two available states – ON or OFF. This means that the control valve is either fully closed or fully open. This is the easiest control method and therefore the least accurate. Depending on the condition of the valve, we either supply too little or too much thermal or cooling energy. This causes the operating status to become unstable, which results in quite significant temperature fluctuations in relation to temperature setpoints.

A special type of the On/Off regulation is PWM – pulse width modulation. The PWM control is an improved version of the On/Off control method.

The “On” signal is maintained for a period proportional to the control error and its duration. As a result, intermediate valve open positions are also achievable. Appropriate adjustment of the pulse width, i.e. heating of liquid and intervals between pulses, allows to maintain the position of the actuator within a certain range between the minimum and maximum open position. Consequently, it contributes to the reduction of temperature oscillation, which occurs in the standard ON/OFF process.

Another control method is the three-point control, where the control signal can take three states – valve opening, closing and stopping. It usually consists in changing the position of the three-way valve, which modifies the proportions of the inlet stream and bypass. The correction of the positioning of the valve’s disc immediately changes the temperature of the mixed water stream. The rapid response of the system allows for minor adjustments to the valve setting. This system requires fast responding systems, otherwise it will operate like the ON/OFF system.

Greater demands and/or more complex control solutions require a control method that allows the result to be changed in more than a few steps. The modulation control uses continuous steps that render it more correct. Continuous control is a broad concept that includes both relatively simple control modes such as proportional control (e.g. thermostats) and more complex control modes such as PID. An example of the continuous control method is the control of the capacity of heaters and coolers in air handling units in order to achieve the pre-set parameters of the supplied air.

When discussing these aspects and the fan coil units distributed by KLIMA-THERM, please be informed that our devices (CLINT, SABIANA) use the ON/OFF control method.

Poland

Poland Sweden

Sweden Finland

Finland German

German Estonia

Estonia