Frequently asked questions

How does the air conditioner work?

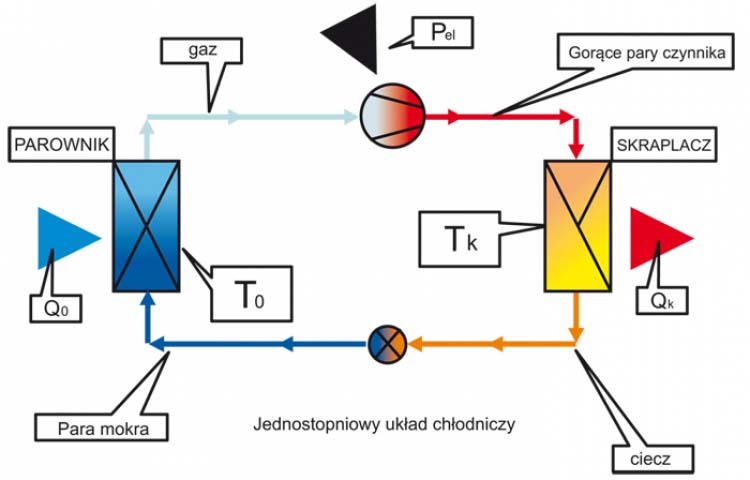

The refrigerant in the form of dry superheated steam is sucked in by the refrigeration compressor through a suction pipe (low pressure, low temperature). The refrigeration compressor compresses the gas and injects it into the refrigeration condenser (high pressure, high temperature).

- In the condenser, the refrigerant condenses at constant pressure and temperature.

- The refrigerant flows in liquid state from the condenser to the tank. From the tank, the liquid refrigerant flows through the supply system to the expansion valve (capillary, electronic expansion valve). The expansion valve causes the isenthalpic expansion of the gas from high pressure (liquefaction) to low pressure (evaporation).

- After expansion, the mixture of liquid and wet steam of the refrigerant flows into the exchanger – the evaporator, where it is completely evaporated to dry steam. The evaporation of the refrigerant is ensured by the air flow through the evaporator fins. The air flowing through the evaporator gives off heat and at the outlet of the air conditioner its temperature and humidity are respectively lower. The refrigerant at the outlet of the evaporator is in the state of dry steam. Dry steam of the refrigerant may overheat between the evaporator and the refrigeration compressor, and in such state the refrigerant is sucked in again by the refrigeration compressor.

For the refrigeration system to work, in addition to building the refrigeration system, it is also necessary to provide an adequate amount of electrical energy, most of which is consumed by the refrigeration compressor to force the refrigerant to circulate in the system. The remaining part enables the work of fans and electronic systems controlling the operation of the device.

The fan assembly is tasked with forcing the air flow through the condenser and evaporator systems.

What factors determine the choice of air conditioner

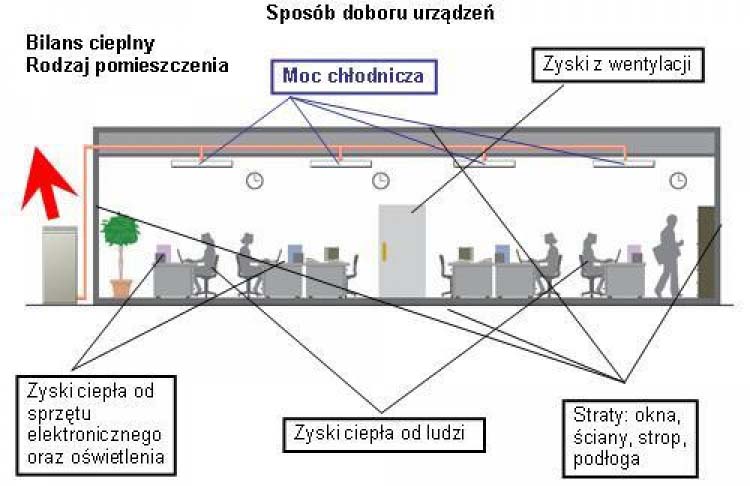

The appropriate selection of the unit's capacity to the prevailing conditions in the room is crucial to the correct operation of the unit.

The parameters that influence the capacity of the unit include:

- human heat gain (depending on the character of the activities performed, we select appropriate gain value)

- Heat gain from electrical and electronic equipment (computers, lighting, etc.)

- Heat gain linked to fresh air ventilation (room ventilation system)

- Heat gain linked to building partition penetration, conduction and radiation (windows, walls, ceiling, floor).

Difference between a conventional device and INVERTER

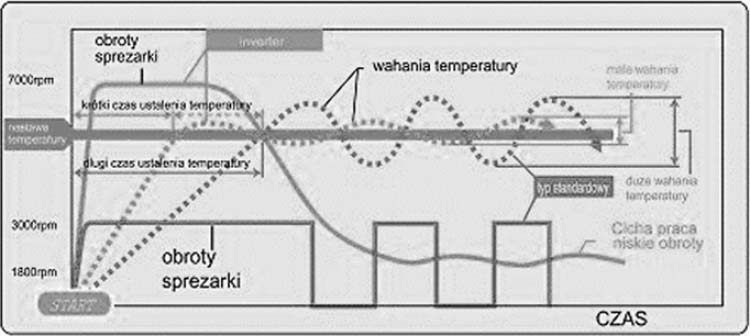

The main purpose of air conditioning is to provide a sense of comfort in the operating area of the unit. When using a conventional fixed capacity device, some problems may occur. However, these problems are completely eliminated if the Inverter technology is used.

ALTERED CAPACITY AT LOW OUTDOOR TEMPERATURES

The INVERTER compressor has the ability to work with higher efficiency, so that the capacity of the device is maintained in a larger range of outdoor temperatures.

LONGER PERIOD OF TIME TO ACHIEVE THE SET TEMPERATURE.

Increasing the power at start-up allows the INVERTER device to reach the desired room temperature faster than a similar conventional device.

SUDDEN TEMPERATURE CHANGES.

Specific operating parameters of conventional devices (ON / OFF) cause temperature fluctuations in the room at ± 1,5ËśC. In the INVERTER devices, thanks to the capacity of the device changing in relation to the demand at a particular point in time, the difference between the room air temperature and the set temperature is within the range of ± 0,5ËśC.

LARGE STARTING CURRENT OF THE COMPRESSOR

The INVERTER device starts with low revolutions, so the starting current is reduced to the minimum.

Air filters used in Fujitsu General units

In order to ensure adequate air flow through the heat exchanger of the indoor unit, it is necessary to use an air filter. Such a filter retains dust particles on its surface, which could otherwise clog the exchanger.

For the most part, Fujitsu GENERAL air conditioners are equipped with standard air filters. The exception are ducted units with the capacity of 7 ÷, 25 kW. Due to the specific installation method of these units, air filters are not included in the set with the new unit, but can be purchased as an option.

Individual types of standard and additional filters:

- Air filter with extended service life (AR*25÷60 devices)

- Automatic air filter with extended service life.

- Plasma filter

- “IONIC” filter with extended service life

- Polyphenol filter

- “PHOTOCATALYTIC” filter with extended service life

- Electrostatic antibacterial “WASABI” filter

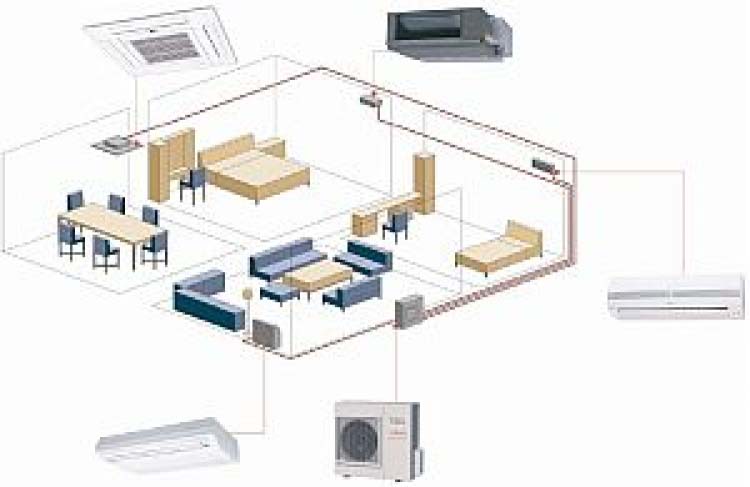

Possibility of selecting Multi inverter units depending on the type

Various models of indoor units (wall mounted, ceiling, ducted, cassette) can be connected to the multi inverter outdoor unit.

The exact description of the permitted combinations for the specific outdoor units can be found in the description of the MULTI INVERTER system.

Whole year operation option

The year-round operation mode allows conventional equipment to operate at low temperatures. By adding the components of the set (fan speed controller and compressor crankcase heater), we are able to ensure appropriate operating conditions for the outdoor unit throughout the year.

Thanks to the variable adjustment of the speed of the outdoor unit’s fan, the condensation pressure remains at the right level. By installing the compressor’s crankcase heater, it is possible to prevent the thickening of the oil and its loss of lubricating properties.

Arctic option

The ARCTIC option facilitates the operation of the devices in heating mode in the winter period. At temperatures < 5ËśC, additional heaters are activated, which prevents the occurrence of undesirable phenomena (freezing of the exchanger of the outdoor unit, freezing of the drip tray, oil thickening).

The set includes: compressor’s crankcase heater, outdoor unit’s drip tray heater, klixon, and additional electric clamp.

How to set the right operation mode?

It is possible to start the device in four different operating modes: cooling, heating, dehumidification, or ventilation. However, the possibility of activating the chosen operating mode depends on the model of the air conditioner.

Cooling only units:

- [COOL] Cooling

- [DRY] Dehumidification

- [FAN] Ventilation

Cooling and heating unit (heat pump):

- [COOL] Cooling

- [HEAT] Heating

- [DRY] Dehumidification

- [FAN] Ventilation

- [AUTO] The air conditioner automatically adjusts the operating mode depending on the temperature settings and ambient conditions.

The AIRSTAGE VRF cooling and heating systems possess additional restrictions. Namely, when any indoor unit is switched on, the entire system is set to the appropriate operating mode. No other, later activated indoor unit may operate in a different mode, e.g.:

- first UNIT ->[COOL] prohibited modes for the other units: HEAT] , [AUTO],

- first UNIT ->[HEAT] prohibited modes for other units: [COOL] , [DRY] , [AUTO]

In the event of an attempt to activate an operating mode that is invalid at that moment using the wireless remote control, a sound signal is generated by the indoor unit (5 short signals).

Unit does not want to turn on

If the indoor unit does not want to switch on (does not react to signals sent from the remote control). The following elements should be checked:

- Check the fuses in the electrical switchboard.

- Check the batteries in the remote control (wireless remote control), replace if necessary.

- Check the LEDs of the indoor unit (red, green, orange); record the combination with which the LEDs are flashing and check the error code against the error list of the unit.

- Check if the operation mode activated by means of the remote control is allowed (try to start it in another COOL, HEAT mode)

- Check if the code of the remote control is identical with the code set on the indoor unit (wireless remote control)

- Check if there is any information on the display of the remote control, otherwise there is no power supply (wired remote control)

- Check if the remote control displays the code error: EE:EE. If this is the case, check the error code against the error list of the unit (wired remote control)

Water drips from the unit, an unpleasant odor is emitted.

- Air conditioners are equipped with air filters. A dirty filter inhibits proper air flow through the radiator, which interferes with the transformation of the refrigerant. As a result, the unit stops cooling and the radiator of the indoor unit freezes. After a longer period of time, water may start dripping from the device. The compressor in the outdoor unit becomes overloaded, which may permanently damage the compressor.

- Air conditioners dehumidify the air at the same time as cooling it down. Water vapour precipitated on the radiator flows down to the drip tray from where it is discharged to the sewer system using gravity or mechanically (drain pump). If the condensate drain to the sewage system is obstructed, the water precipitated during the air cooling process will gather in the drip tray and after exceeding its capacity it will be discharged in the room where the air conditioner is installed.

- If the unit is equipped with a drain pump, optionally or as standard (AU* - cassette type), the float from which the signal activates the pump should be cleaned as part of periodic maintenance. Any contamination in the condensate tray may cause the float to become blocked in the position signalling the pump activation, which will lead to dry running and consequent damage of the pump.

- An incorrectly installed condensate drain system (no siphons, no venting, excessively small pipe diameter) may not collect enough water.

- The absence of siphons in the condensate drain system allows unpleasant odours from the sewage system to enter the indoor unit, blasting them into the room together with the treated air.

- The indoor unit radiator and drip tray are exposed to high levels of humidity. If the air conditioner is not cleaned on a regular basis, this can lead to the development of various bacteria, fungal spores and moulds (especially in a humid environment). To prevent unpleasant odours, make sure to clean the machine regularly. The intervals between cleaning operations depend on the conditions in which the unit operates, but should not be less frequent than twice a year.

Poland

Poland Sweden

Sweden Finland

Finland German

German Estonia

Estonia