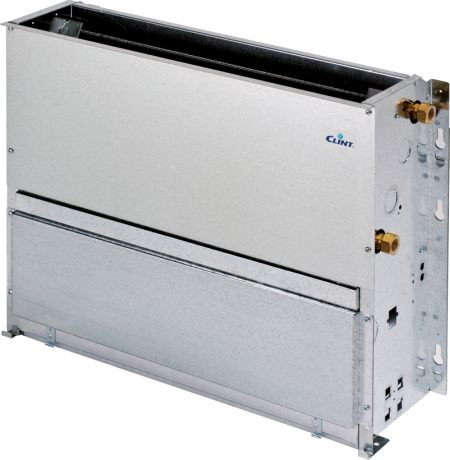

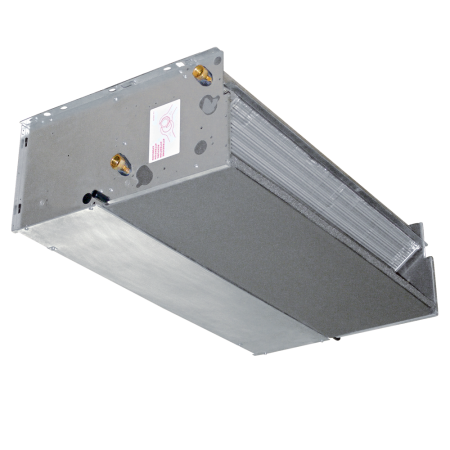

The TIP line of precision air conditioners is the most advanced solution for technological applications in facilities such as: server farms, power amplifier rooms of UMTS and GSM transmitters, NOCs (Network Operations Centre), cooling of computer racks, control rooms, power supply devices, and practically anywhere where heat loads are extremely high.

This device type is especially dedicated to systems where the main focus is on reliability, safety and air conditioning redundancy. These units are characterised by the availability of two separate operating modes, using two different coolers working in supporting and backup mode: primary fed with chilled water and secondary through direct evaporation.

Poland

Poland Sweden

Sweden Finland

Finland German

German Estonia

Estonia